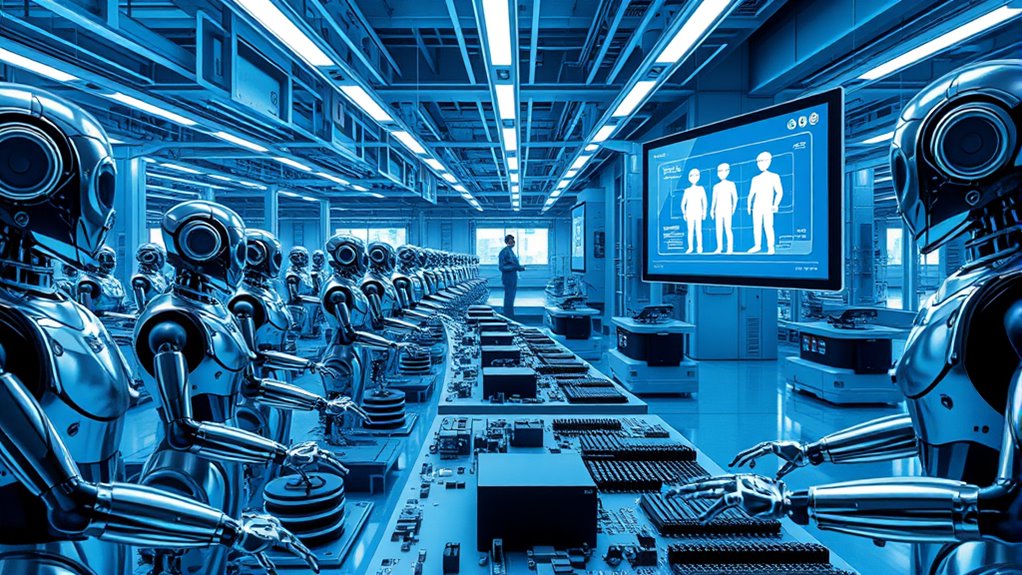

By 2030, automation with advanced robotics, AI, and IoT will transform your industry by boosting efficiency, cutting costs, and streamlining workflows. Smarter factories will rely on real-time data, sensors, and automation to improve quality and safety. Countries leading in innovation will set the pace, while others face challenges like skill gaps and cybersecurity risks. Staying ahead means understanding these changes, and you’ll discover how to adapt as this revolution unfolds.

Key Takeaways

- Industry 4.0 will drive widespread automation, transforming manufacturing, logistics, and service sectors through AI, IoT, and robotics by 2030.

- Robotics will enhance precision, speed, and safety, reducing errors and enabling flexible, data-driven production workflows.

- Automation is projected to create 170 million new jobs while displacing around 92 million roles globally.

- Regional leaders like Asia Pacific will spearhead innovation, with industries such as MedTech and food & beverage leading growth.

- Challenges include job displacement, cybersecurity threats, and the need for workforce reskilling to adapt to fully automated industries.

The Rise of Industry 4.0 and Its Impact on Manufacturing

Industry 4.0 is transforming manufacturing by integrating advanced technologies like AI, IoT, and robotics to increase efficiency and productivity. You’ll see smarter factories that rely on data-driven decisions and automation, streamlining operations and reducing costs. Countries like China and the USA lead the way, adopting these innovations to stay competitive in the global market. However, some regions face hurdles such as outdated IT systems and a lack of skilled workers, slowing progress. This shift redefines jobs, emphasizing skills in data analysis, technical knowledge, and digital tools. Manufacturers are also outsourcing roles related to technology, cybersecurity, and data management. Overall, Industry 4.0 elevates manufacturing, making it more agile, sustainable, and capable of meeting evolving market demands. Investment in digital infrastructure and workforce skills continues to be crucial for successful adoption. As a result, tuning techniques in various automotive sectors are increasingly integrated with digital tools to optimize performance and durability. Additionally, addressing technology integration challenges is essential for maximizing the benefits of automation in manufacturing processes. Furthermore, the rapid advancement of cybersecurity measures is vital to protect sensitive data and ensure the integrity of automated systems. The adoption of sound healing science principles and other innovative approaches can support worker well-being in highly automated environments. Embracing digital transformation and fostering continuous learning are vital for industries to thrive in this new landscape.

Key Technologies Transforming Automation and Their Applications

Advancements in key technologies are driving a new wave of automation that’s reshaping how manufacturing operates. These innovations are enabling smarter, faster, and more efficient processes. AI improves decision-making and learning, while IoT connects devices for real-time data exchange. Cloud computing offers scalable storage and processing, and edge computing reduces latency by processing data close to sources. 5G connectivity boosts data transfer speed and reliability. Here’s a quick overview:

| Technology | Application |

|---|---|

| Artificial Intelligence | Predictive maintenance, quality control |

| Internet of Things | Supply chain, real-time monitoring |

| Cloud Computing | Data storage, system scalability |

| Edge Computing | Low-latency data processing |

| 5G Connectivity | Faster, reliable communication |

These technologies are transforming manufacturing into more connected, efficient, and resilient systems. As a result, AI security concerns are increasingly important to ensure the safety and integrity of automated processes. Retail hours and other service industry schedules are adapting to this technological shift, impacting how businesses operate and serve customers. For example, the integration of these technologies can also enhance industry-specific safety protocols and operational efficiency. Additionally, the development of Honda Tuning modifications exemplifies how industry-specific innovations can improve vehicle performance and customization options. Furthermore, the focus on noise levels of modern heat pumps highlights how technological advancements are also improving comfort and environmental standards across various sectors.

How Robotics and Sensors Are Redefining Production Lines

Robotics and sensors are boosting production lines by increasing both precision and speed, allowing tasks to be completed faster and more accurately. You can now monitor operations in real-time, catching issues early and optimizing workflows instantly. This integration guarantees your manufacturing processes are more efficient and adaptable to changing demands. Analytical AI enables data processing from sensors to further enhance operational insights and decision-making. For example, sustainable materials can be incorporated into products to meet eco-conscious consumer demands. Additionally, incorporating natural materials and authentic design elements also helps create a more inviting and personalized environment, whether in a farmhouse bedroom or industrial setting. This focus on personality test insights can foster a more engaging workspace for employees. Furthermore, implementing Ford Tuning techniques into manufacturing automation can optimize engine-driven machinery, improving overall system performance and durability. Additionally, integrating comfort solutions into workspaces can improve worker well-being and productivity.

Enhanced Precision and Speed

As automation continues to evolve, intelligent robots equipped with advanced sensors are transforming production lines by delivering unmatched precision and speed. You’ll notice how these robots reduce errors, ensuring higher product quality with consistency. Their ability to operate at speeds humans can’t match considerably boosts efficiency and production rates. Plus, their flexibility allows quick adaptation to different tasks and lines, making your manufacturing process more agile. With sensors improving safety and interaction, robots can work alongside humans safely. They also help cut labor costs by automating repetitive tasks. The robotics industry is projected to reach $218 billion in 2030, with technological breakthroughs driving this growth. Key benefits include:

- Precise automation for consistent quality

- Faster production speeds

- Flexible programming for various tasks

- Enhanced safety through sensor tech

- Cost reductions via automation

Real-Time Data Monitoring

Real-time data monitoring is transforming production lines by enabling continuous tracking of key metrics through sensors and robotics. You’ll see data collected instantly from IoT devices embedded in machines, tools, inventory, and even worker wearables. This constant flow of information allows for immediate insights, empowering you to make faster, smarter decisions. With sensors and robotics working together, production processes become more efficient, reducing downtime and optimizing resource use. Real-time monitoring is at the heart of Industry 4.0, making factories smarter and more connected. It also supports predictive maintenance, preventing costly breakdowns, and enables dynamic control over operations. As edge computing processes most data locally, latency drops, and insights accelerate, giving you an indispensable competitive edge in today’s rapidly evolving market. Real-time data collection enhances the ability to identify inefficiencies early, allowing for proactive adjustments and continuous process improvement.

The Economic and Social Shifts Driven by Increased Automation

The rise of automation is set to reshape both the economy and society considerably by 2030. You’ll see a $15.7 trillion boost to the global economy, driven mainly by productivity ($6.6 trillion) and consumption effects ($9.1 trillion). This shift will create around 170 million new jobs but displace 92 million others worldwide. Economic structures may change dramatically, with emerging markets potentially leapfrogging developed ones. However, the increased prevalence of cheating in online interactions highlights the need for ethical considerations in technological advancements. Additionally, understanding the diverse personality traits of individuals impacted by these changes can facilitate better adaptation and communication during this transitional period Personality Exploration, emphasizing the importance of technological literacy in navigating future societal shifts. Recognizing the importance of ethical frameworks is essential to guide responsible innovation and maintain public trust in emerging technologies. Developing Cultural Intelligence can also support organizations and individuals in managing cross-cultural challenges that arise during rapid technological change.

Regional Leaders in Automation Innovation and Investment

Growing investment in automation across regions highlights shifting global leadership, with Asia Pacific emerging as a key driver of growth. This region is experiencing rapid expansion, fueled by markets outside Europe, which lag behind in process automation. Meanwhile, sectors like pharmaceuticals, MedTech, and food & beverage are leading innovation, especially in hybrid industries with high CAGRs. Major players like Samsung Electronics and newer entrants such as Samsung Electro-Mechanics are pushing technological boundaries. The role of global intelligence in tracking and supporting these developments is more critical than ever to understand regional influences and investment patterns. Additionally, regional policies and industry-specific regulations can significantly impact the pace and direction of automation adoption, influencing the market dynamics and competitive landscape. As these factors evolve, they further underscore the importance of AI-driven analysis in shaping strategic decisions within the automation sector. Moreover, advancements in robotic technologies are accelerating the integration of automation into various industries, reshaping traditional workflows and workforce requirements.

Challenges and Risks Associated With Widespread Automation Adoption

As automation accelerates worldwide, organizations face a complex web of challenges and risks that could hinder widespread adoption. You’ll need to manage job displacement, as up to 92 million roles could disappear globally by 2030, while new jobs emerge in AI and automation. Technological hurdles also loom, with 39% of skills expected to become outdated between 2025 and 2030, and many organizations lacking the infrastructure for effective AI deployment. Social risks include increased unemployment among low-skilled workers and rising social inequality if these changes aren’t managed carefully. Operational risks pose threats like dependency on technology, cybersecurity breaches, and supply chain disruptions. Addressing biases, privacy issues, and regulatory lag remains critical to make sure that automation benefits everyone without exacerbating existing inequalities. Additionally, the rapid evolution of paint sprayer technology highlights how industry standards and safety protocols must adapt swiftly to keep pace with innovation. Moreover, the importance of training and reskilling programs becomes apparent as the workforce needs to adapt to new technological demands.

Future Trends: Sustainability, Security, and Global Standards

As automation advances, you’ll see a stronger focus on sustainability through energy-efficient practices and resource optimization. Security becomes even more critical as industries adopt smarter systems, requiring robust cybersecurity measures. Meanwhile, global standards are evolving to guarantee interoperability and consistent regulations across borders, shaping industry practices worldwide.

Sustainable Automation Practices

Sustainable automation practices are shaping the future of manufacturing by emphasizing efficiency, environmental responsibility, and global standards. By adopting these practices, you can optimize resource use, cut waste, and lower energy consumption. Automation helps industries reduce their carbon footprint since about one-third of all CO2 emissions come from manufacturing. Companies like Advanced Composite Structure have used automation to decrease scrap rates from 24% to 1.8%, boosting efficiency and sustainability. Real-time environmental impact tracking allows you to monitor and improve your ecological footprint. Additionally, integrating advanced robotics, IIoT, and AI enhances resource management and reduces emissions. Global standards and regulations push industries toward more sustainable practices, ensuring consistent progress worldwide and aligning with initiatives like the UN’s Sustainable Development Goals.

- Resource optimization and waste reduction

- Carbon footprint minimization

- Real-time environmental tracking

- Scrap rate improvements

- Adoption of advanced robotics and IIoT

Enhanced Cybersecurity Measures

The increasing frequency of cyberattacks and rapid technological advancements are driving the need for more robust cybersecurity measures in industrial automation. You’ll face threats like phishing, ransomware, and complex intrusions that demand smarter, automated defenses. AI, machine learning, and big data analytics enhance security tools, enabling real-time threat detection and rapid response. With a shortage of skilled cybersecurity professionals, automation becomes essential to fill gaps and maintain protection. Strict regulations in sectors like finance and healthcare push organizations to adopt stronger security protocols. As IoT devices and cloud services expand, all-encompassing security measures become even more critical. You’ll see the rise of zero-trust architectures, behavioral analytics, and multi-layered security to safeguard industrial systems against evolving threats.

Global Regulatory Harmonization

With the rapid pace of technological and regulatory changes shaping industrial sectors, aligning standards across countries has become more important than ever. Regulatory harmonization streamlines approval processes, reduces duplication, and enables easier access to global markets. It’s vital for sectors like pharmaceuticals, medical devices, and biotech, where safety and efficiency matter. International forums like APEC lead these efforts, developing shared frameworks and best practices. This approach minimizes time and costs, helping you focus on innovation instead of compliance. It also fosters a predictable environment for investment and faster deployment of new technologies. Emerging tools, such as AI-driven platforms and cloud-based solutions, further accelerate harmonization. These innovations promote real-time data sharing and transparency, ensuring safety standards keep pace with rapid technological advancements.

- Standardized procedures across borders

- Reduced regulatory costs and delays

- Enhanced global market access

- Adoption of digital, AI-powered tools

- Collaboration among governments and industry

Preparing the Workforce for a Fully Automated Future

Preparing for a fully automated future requires proactive strategies to help workers adapt to rapid technological changes. You’ll need to focus on reskilling and upskilling, as automation could displace up to 800 million jobs by 2030. Many workers, potentially 75 to 375 million, will have to switch occupational categories and learn new skills. Countries like China face significant shifts, with around 100 million workers needing retraining. To thrive, you must embrace continuous learning, develop digital literacy, and focus on complex problem-solving, creativity, and innovation. Employers and governments should collaborate on workforce transition programs to support occupational shifts. By investing in education and training now, you’ll better navigate the economic and social changes driven by automation and AI’s global impact.

Frequently Asked Questions

How Will Automation Affect Small and Medium-Sized Enterprises?

Automation will transform your SME by boosting efficiency and reducing costs, letting you focus on strategic growth. It can improve employee satisfaction by automating routine tasks and create new market opportunities worth millions. While some resistance may occur, overall, automation helps you increase productivity, redesign jobs, and accelerate decision-making. Embracing these changes positions your business for future success, enabling you to stay competitive and capitalize on the expanding automation landscape.

What Are the Best Strategies to Retrain Displaced Workers?

You should prioritize rapid, employer-led retraining programs focused on automation-related skills. Engage in industry-specific reskilling initiatives, especially in manufacturing, where many jobs are at risk. Leverage technology-enabled platforms, like AI-driven training and digital learning, to make reskilling efficient and accessible. Collaborate with government and academia to expand resources, ensuring displaced workers quickly adapt to new roles, maintaining full employment and economic growth.

How Can Industries Ensure Cybersecurity in Highly Automated Systems?

You can guarantee cybersecurity in highly automated systems by integrating AI and ML for real-time threat detection, automating security measures to reduce human error, and investing in advanced blockchain technology for data protection. Regularly updating legacy systems, conducting simulated phishing attacks, and staying compliant with regulations also strengthen defenses. Additionally, prioritize employee training and foster a security-first culture to minimize vulnerabilities and respond swiftly to emerging threats.

What Legal Frameworks Will Regulate Autonomous Industrial Robots?

You’ll need to navigate evolving legal frameworks that regulate autonomous industrial robots. Expect new laws addressing liability when accidents happen, safety standards, and data privacy. These regulations should promote transparency, accountability, and secure data handling. International cooperation will be essential to harmonize standards across borders. By staying informed and advocating for clear policies, you can help guarantee these regulations protect public safety, foster innovation, and address ethical concerns effectively.

How Will Automation Influence Global Supply Chain Resilience?

Imagine a supply chain as a finely tuned orchestra, where automation acts as the conductor, guiding every instrument seamlessly. You’ll see faster responses to disruptions, real-time tracking, and smarter decision-making. This resilience means your industry can adapt swiftly to shocks, reduce delays, and maintain steady operations. Automation’s integration creates a robust network that withstands unexpected challenges, ensuring your supply chain stays strong, flexible, and ready for whatever comes next.

Conclusion

As automation takes over, you might find yourself marveling at a perfectly efficient, robot-run world—while the human touch becomes a distant memory. Ironically, in aiming for endless productivity, we could lose the very creativity and nuance that make industries thrive. So, as machines do it all, don’t forget to ask: who’s really in control? Because sometimes, the biggest surprise is how little surprise there’ll be when everything’s automated.