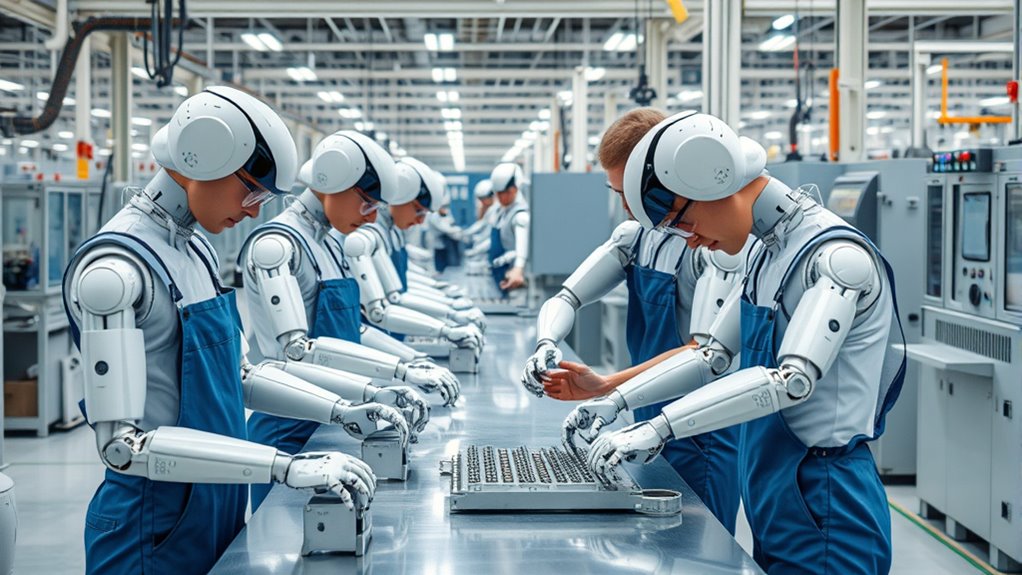

Cobots are transforming factory floors by working alongside humans, boosting productivity, safety, and flexibility. They handle repetitive or hazardous tasks, allowing workers to focus on more skilled roles. Cobots are affordable, easy to reprogram, and support continuous operation, making manufacturing more efficient. They also improve workplace safety by reducing injuries. If you explore further, you’ll discover how these innovative robots are shaping the future of manufacturing and workforce collaboration.

Key Takeaways

- Cobots enable safe collaboration by performing hazardous, repetitive, and physically demanding tasks alongside human workers without physical barriers.

- They increase flexibility, allowing quick reprogramming and redeployment for various tasks, enhancing overall manufacturing efficiency.

- Cobots operate continuously, boosting productivity and ensuring consistent quality on the factory floor.

- They improve workplace safety and worker well-being by reducing physical strain and handling dangerous operations.

- Integration of AI and vision systems ensures real-time monitoring, defect detection, and adaptive responses during human-robot collaboration.

Top picks for "automation factory floor"

Open Amazon search results for this keyword.

As an affiliate, we earn on qualifying purchases.

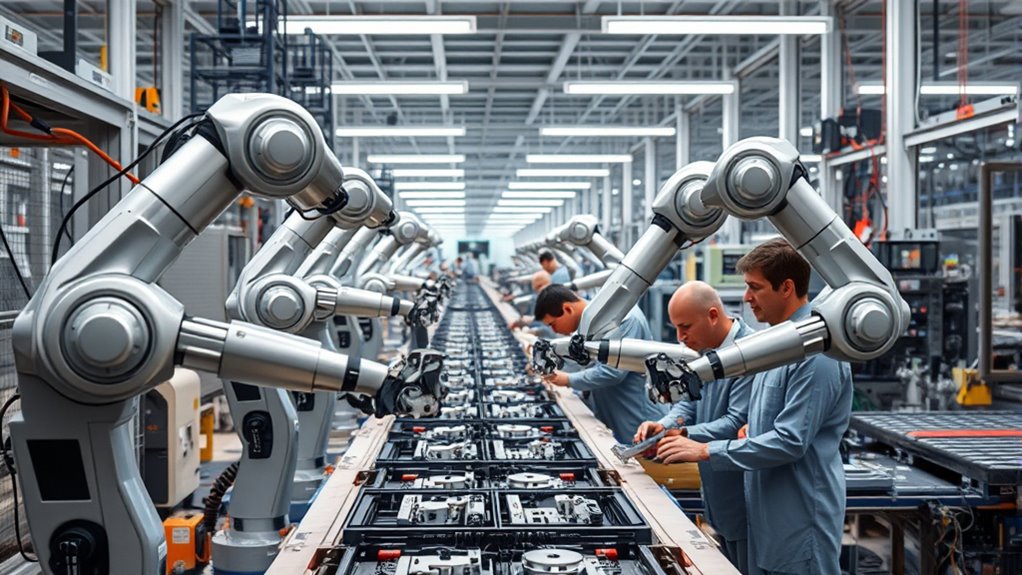

The Rise of Collaborative Robots in Manufacturing

The rise of collaborative robots, or cobots, is transforming manufacturing by enabling humans and machines to work side by side safely and efficiently. You now see cobots handling repetitive and hazardous tasks, freeing up workers for more skilled roles. Their affordability and flexibility make them accessible to a wide range of industries, from life sciences to food production. As costs decline 3–5% annually, more companies adopt cobots to address labor shortages, increase productivity, and improve safety. These robots operate continuously without breaks, ensuring consistent quality and faster throughput. Their ability to be quickly reprogrammed for new tasks makes them ideal for dynamic production environments. Additionally, cookie management practices can enhance the integration of digital tools and data analytics in manufacturing settings. Overall, cobots are reshaping the factory floor, fostering safer workplaces, and driving operational excellence.

Key Industries Embracing Cobot Technology

Multiple industries are rapidly adopting cobot technology to enhance productivity, safety, and flexibility. You’ll find cobots in life sciences, pharma, and biomed sectors, where precision and safe human collaboration are essential. Food and consumer goods industries use cobots for quick reconfiguration and hygienic operations, meeting fast-changing demands. Automotive manufacturers, like Tesla and BMW, leverage cobots to streamline assembly lines, while the plastics and rubber sectors utilize them for flexible processing. Logistics, warehousing, and healthcare also embrace cobots for repetitive, physically demanding tasks, reducing injuries and increasing efficiency. Industries with rapid product cycles or high customization, such as electronics and semiconductors, see significant benefits from cobots’ adaptability. Overall, these sectors recognize cobots as indispensable tools to boost competitiveness and operational agility.

Operational Advantages of Working With Cobots

Working with cobots boosts your production capacity by enabling continuous, around-the-clock operation without breaks. They also improve workplace safety by taking on dangerous and repetitive tasks, reducing injuries and strain. Plus, their flexibility allows you to automate different tasks quickly, adapting to changing demands with minimal disruption. Additionally, integrating collaborative robots can enhance overall efficiency by seamlessly working alongside human operators.

Increased Production Capacity

Cobots substantially boost production capacity by allowing factories to operate around the clock without breaks, effectively increasing throughput. They handle repetitive tasks continuously, reducing downtime and maximizing output. This consistent performance means you can meet higher demand without hiring additional staff or expanding facilities.

| Benefit | Impact | Example |

|---|---|---|

| 24/7 Operation | Higher throughput | Continuous production shifts |

| Reduced Downtime | Fewer delays | Quick task reconfiguration |

| Flexibility | Adapt to new products | Rapid line changes |

| Consistent Quality | Less waste | Minimized defects |

Enhanced Worker Safety

Integrating cobots into manufacturing environments considerably enhances worker safety by taking over hazardous, monotonous, and physically demanding tasks. You’ll notice a significant reduction in workplace injuries, with up to 70% fewer incidents compared to traditional manual work. Cobots handle dangerous operations like heavy lifting, exposure to toxic substances, or repetitive motions that cause strain and injury. Their advanced AI vision systems monitor the floor for hazards such as spills, unauthorized entry, or missing PPE, sending instant alerts to prevent accidents. Unlike traditional automation, cobots work safely alongside humans without physical barriers or cages. This collaboration creates a safer, healthier workplace, reduces fatigue, and lowers long-term health risks, ultimately supporting worker well-being and addressing labor shortages. Gold IRA rollovers can also serve as a strategic financial safety net for workers planning for retirement security amidst economic uncertainties.

Flexible Task Automation

Flexible task automation with cobots allows manufacturing facilities to quickly adapt to changing production needs and product lines. You can reprogram and redeploy cobots in minutes, enabling smooth progressions between tasks. Imagine:

- Swapping out end-effectors to handle different parts, from tiny electronics to large packaging.

- Adjusting programming on-the-fly for new product specifications without halting production.

- Moving cobots effortlessly to different stations or lines to meet fluctuating demand.

- Integrating AI-driven updates that optimize performance based on real-time data.

- Easy-to-maintain cobot systems contribute to long-term operational efficiency and reduce downtime.

This agility means you’re not locked into rigid automation setups. Instead, your facility becomes more responsive, reducing downtime and increasing efficiency. Cobots empower you to stay competitive in fast-changing markets, all while minimizing costs and maximizing productivity.

Enhancing Workplace Safety and Worker Well-being

By integrating cobots, you can considerably cut workplace injuries, especially from repetitive or hazardous tasks. These robots handle the dirty, dull, and dangerous work, reducing physical strain and ergonomic risks for your workers. With AI vision systems monitoring safety hazards in real-time, you create a safer environment that promotes well-being and minimizes accidents. Additionally, implementing family dynamics insights can foster a more supportive and collaborative workplace culture.

Reducing Workplace Injuries

Advancements in collaborative robot (cobot) technology are considerably enhancing workplace safety by taking on hazardous, repetitive, and physically demanding tasks. This shift reduces the risk of injury and creates a safer environment. Picture these improvements:

- Cobots handle heavy lifting, preventing back injuries and strains.

- They perform dangerous tasks like welding or chemical handling, keeping humans out of harm’s way.

- AI vision systems monitor for hazards—such as spills or unauthorized access—sending instant alerts.

- Cobots operate safely alongside workers without physical barriers, reducing accidents caused by human error.

- Integrating wall organization systems with cobot stations can further streamline workflows and improve safety protocols.

Improving Ergonomic Conditions

Implementing cobots in manufacturing environments considerably improves ergonomic conditions by reducing physical strain and repetitive motions that often lead to musculoskeletal disorders. You’ll notice fewer worker injuries related to lifting, twisting, or maintaining awkward postures. Cobots take over dull, physically demanding tasks, allowing you to focus on supervision, quality control, and maintenance. Their ability to operate alongside humans safely means you don’t need barriers or cages, creating a more comfortable workspace. AI vision systems and sensors monitor for hazards like spills or missing PPE, sending instant alerts to prevent accidents. This proactive safety approach, combined with reduced physical fatigue, boosts overall worker well-being. Incorporating mindfulness techniques can further enhance worker focus and stress management in demanding environments. As a result, workplaces become safer, more appealing, and better suited to retain skilled employees amid labor shortages.

Economic Impact and Strategic Benefits for Manufacturers

The economic impact of cobots on manufacturing is profound, offering strategic advantages that can help companies stay competitive in a shifting global landscape. You can:

- Visualize increased productivity with cobots working nonstop, handling tasks around the clock, reducing bottlenecks.

- Imagine lowering costs as cobots become more affordable, allowing you to reallocate resources to innovation and growth.

- Picture filling workforce gaps effortlessly, maintaining output despite labor shortages or high turnover.

- Envision quick redeployment of cobots to adapt to new products or market demands, keeping your operations agile.

- Recognize how integrating best practices in automation can maximize your cobots’ efficiency and longevity.

These benefits lead to improved margins, enhanced competitiveness, and resilience against economic uncertainties. Investing in cobots isn’t just about automation; it’s a strategic move to future-proof your manufacturing capabilities.

Technological Innovations Driving Cobot Adoption

Innovative technologies are transforming how cobots are integrated into manufacturing processes, making them smarter, more adaptable, and easier to deploy. AI and machine learning enable cobots to adjust in real-time and predict maintenance needs. Vision systems with AI-driven defect detection improve quality and reduce waste. Augmented Reality (AR) tools assist maintenance with remote guidance, speeding repairs. These advancements create an ecosystem where humans, cobots, and AI work seamlessly together. Additionally, Kia Tuning techniques demonstrate how customization and optimization can enhance vehicle performance, reflecting a broader trend toward tailored technological solutions. Visualize this evolution:

| Technology | Functionality | Impact |

|---|---|---|

| AI & Machine Learning | Real-time adjustments, predictive maintenance | Increased flexibility and uptime |

| Vision Systems | Defect detection, quality control | Higher quality, less waste |

| AR Tools | Remote diagnostics, training | Faster repairs, better maintenance |

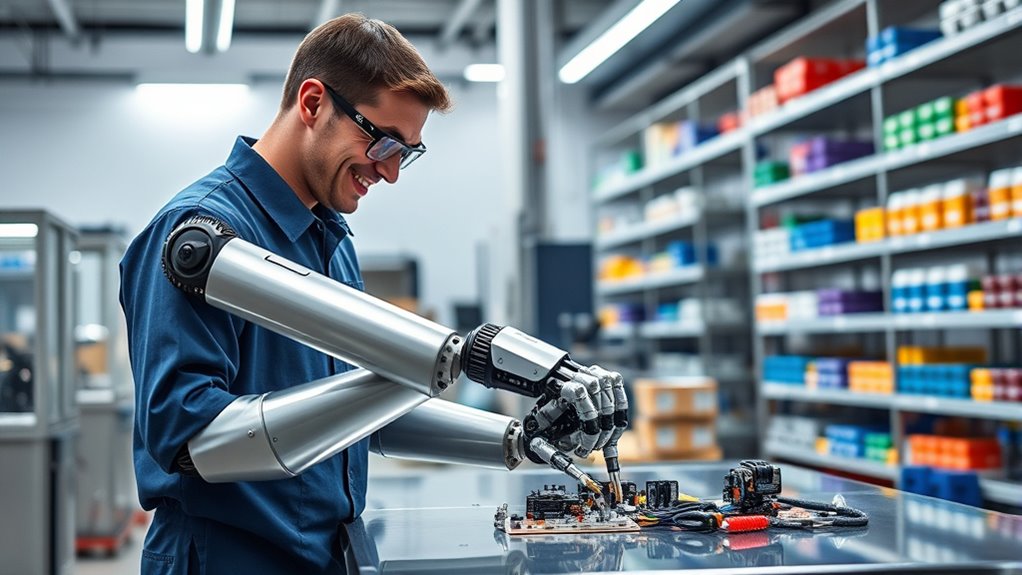

Skills and Training for Hybrid Human-Robot Workforces

As cobots become more intelligent and adaptable through advances in AI, vision systems, and AR tools, the human workforce must evolve alongside these technologies. You’ll need new skills to work effectively with robots, from programming basic tasks to troubleshooting complex systems. Consider these key areas:

- Visualize yourself learning to interpret AR overlays that guide maintenance or adjustments.

- Imagine gaining confidence in programming cobots to handle different tasks with minimal downtime.

- Picture yourself analyzing data dashboards to optimize production lines in real-time.

- Envision collaborating seamlessly with AI-driven systems while maintaining safety and efficiency.

- Familiarize yourself with Water Parks, which often incorporate advanced water management and safety systems that require skilled oversight.

These skills empower you to supervise, troubleshoot, and adapt quickly, ensuring the human-robot partnership boosts productivity and safety on the factory floor.

Overcoming Challenges and Barriers to Integration

Implementing cobots in manufacturing settings often faces hurdles such as high initial costs, workforce resistance, and integration complexities. You might worry about the upfront investment or employee pushback. To overcome these barriers, you need strategic planning and clear communication. Partnering with vendors for training and support eases integration. You also must demonstrate the long-term benefits, like increased safety and productivity. Here’s a quick snapshot:

| Challenge | Solution | Benefit |

|---|---|---|

| High upfront costs | Phased implementation, ROI analysis | Cost savings over time |

| Workforce resistance | Employee involvement, training | Smooth transition |

| Integration complexity | Vendor support, modular systems | Faster deployment |

| Safety concerns | Rigorous testing, safety protocols | Worker confidence |

| Technological skills | Upskilling programs | Competent workforce |

The Future Landscape of Human-Cobot Collaboration

Looking ahead, human-cobot collaboration is set to become more seamless and dynamic, reshaping factory workflows. You’ll experience smarter cobots that adapt in real-time, working side-by-side without barriers. Imagine:

Human-cobot collaboration will become seamless and dynamic, transforming factory workflows through smarter, adaptive robots working alongside humans.

- Cobots anticipating your needs, adjusting their actions instantly through AI learning.

- Factory floors transforming into intelligent ecosystems with interconnected robots and humans.

- Maintenance becoming faster, with AR tools guiding you remotely for quick repairs.

- Workers shifting into supervisory and programming roles, leveraging data literacy and AI skills.

This evolution will make operations more flexible, safer, and efficient. Cobot costs continue to decline, broadening adoption. The future promises a harmonious blend of human intuition and machine precision, driving productivity and innovation to new heights.

Frequently Asked Questions

How Do Cobots Adapt to Different Manufacturing Tasks in Real Time?

You can see cobots adapt to different manufacturing tasks in real time through AI and machine learning. They analyze data from sensors and vision systems to adjust their actions instantly, whether it’s changing speed, grip, or movement patterns. This flexibility allows them to switch tasks quickly, optimize performance, and maintain quality without manual reprogramming, making your production line more efficient and responsive to changing demands.

What Cybersecurity Measures Are Recommended for Connected Cobot Systems?

Think of your connected cobot system as a fortress needing guards. You should implement strong firewalls, encrypt data in transit and at rest, and regularly update software to patch vulnerabilities. Use multi-factor authentication for access, monitor network activity for suspicious behavior, and segment your network to isolate the cobots. Training staff on cybersecurity best practices is essential—your cobots are as secure as the defenses you build around them.

How Do Cobots Impact Long-Term Employment and Workforce Dynamics?

You’ll find that cobots reshape long-term employment by supplementing human workers, taking on repetitive, dangerous tasks, and boosting safety. While some jobs may shift or require new skills, overall, cobots create opportunities for workers to focus on higher-value, supervisory, or technical roles. This evolving workforce dynamic encourages ongoing training and collaboration, leading to more flexible, safer workplaces that adapt to industry changes and improve productivity over time.

What Are the Maintenance Requirements for Ai-Driven Cobot Systems?

Think of maintaining AI-driven cobots as nurturing a high-performance team member. You’ll need to perform regular software updates, system calibrations, and sensor checks to keep everything running smoothly. Monitoring AI algorithms and vision systems guarantees they adapt correctly, reducing downtime. Predictive maintenance, guided by AI insights, helps you address potential issues early. By staying proactive, you maximize cobots’ efficiency and longevity, ensuring your factory remains agile and productive.

How Do Companies Measure ROI From Cobot Integration Effectively?

You measure ROI from cobot integration by tracking increased productivity, reduced labor costs, and fewer safety incidents. Focus on quantifiable metrics like throughput, defect rates, and downtime. Consider the cost savings from minimized injuries and improved ergonomics. Use pre- and post-implementation data to analyze efficiency gains and payback periods. Regularly review these metrics to guarantee continuous improvement and justify your investment in cobots.

Conclusion

As you navigate the evolving factory floor, think of cobots as your trusted partners in a dynamic dance—each step synchronized to boost efficiency and safety. Embracing this collaboration isn’t just a trend; it’s the rhythm of future manufacturing. By integrating cobots seamlessly into your operations, you’re not only staying ahead of the curve but also shaping a smarter, safer, and more resilient workplace. The future of work is a team effort, and cobots are here to lead the way.